3D Metal Printing

First machine shop in Alberta to offer advanced composite and metal printing

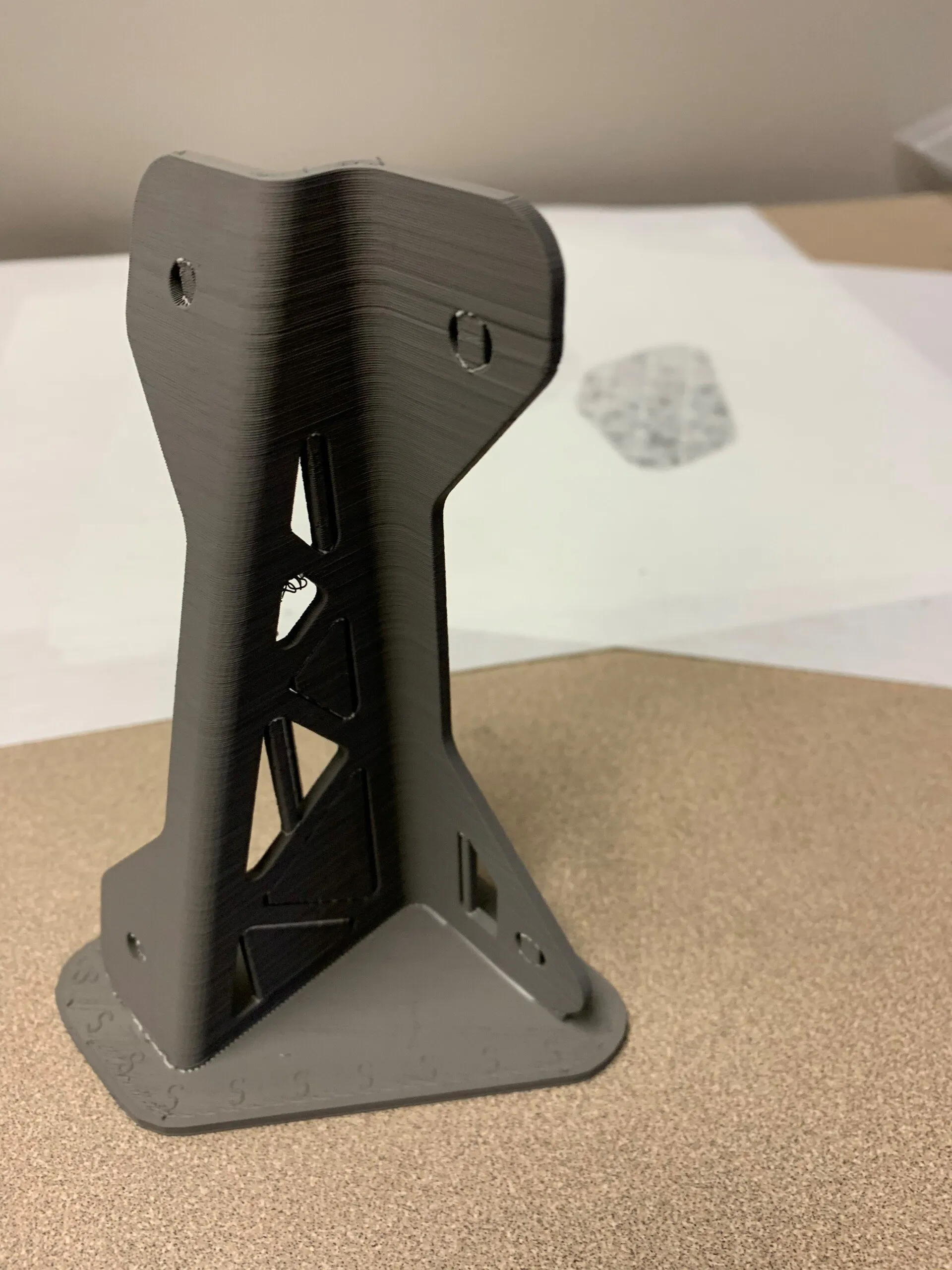

Composite and Metal 3D Printing

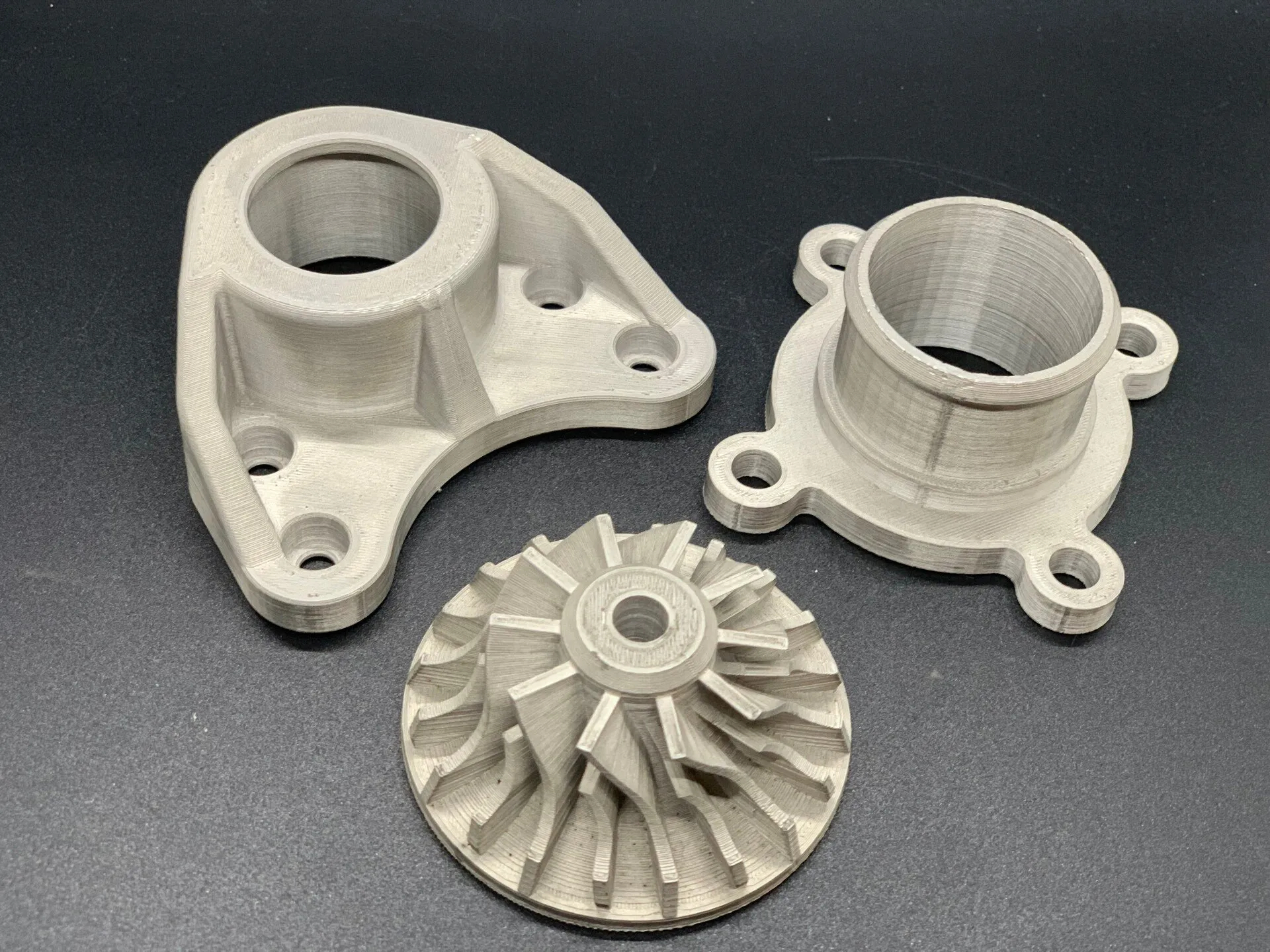

Industrial 3D printing technology offers the precision and quality to produce prototypes and custom parts that were once impossible with conventional machining equipment. By integrating 3D metal printing into our machine shop, we are removing barriers between conception and build.

- 3D metal printing

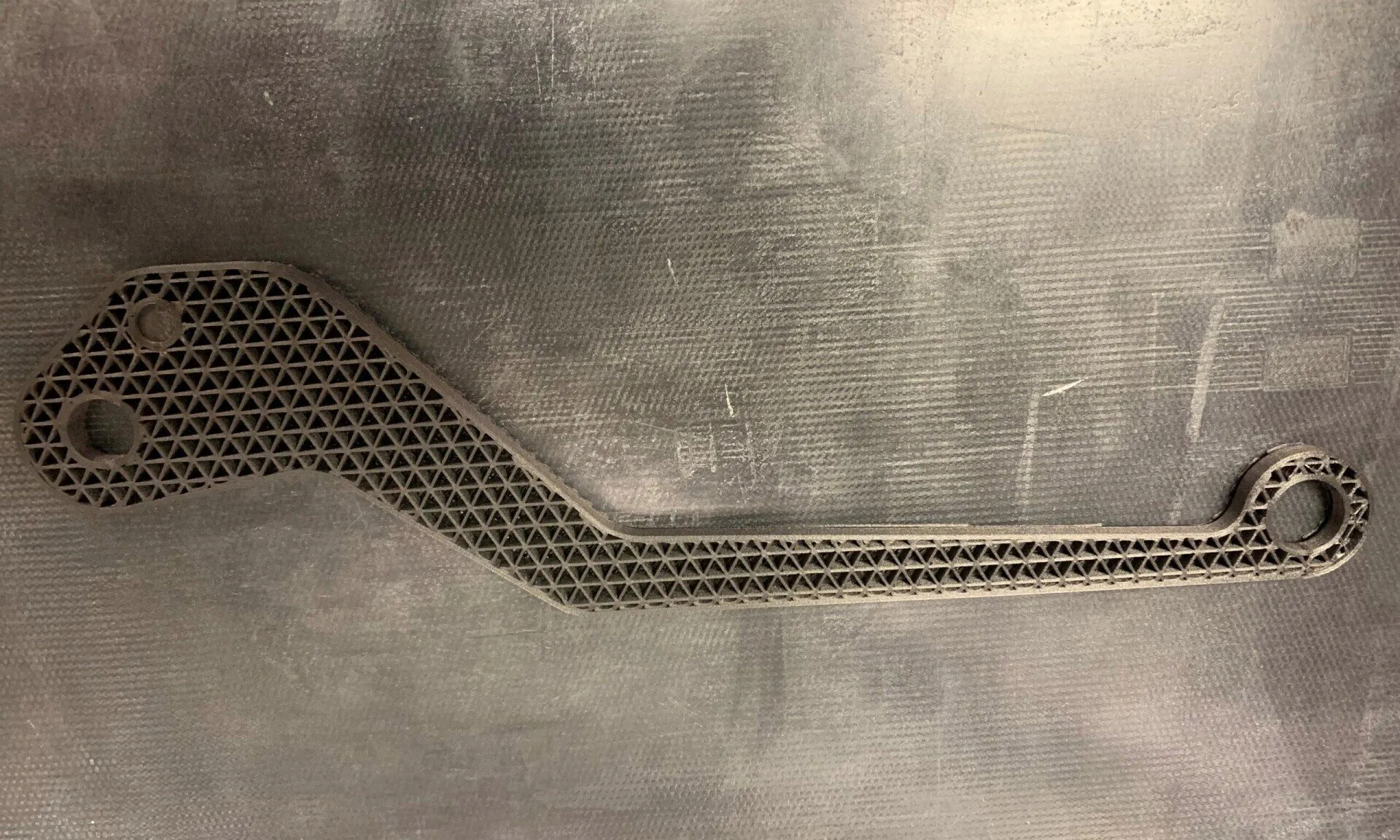

- CFR composite printing

- Rapid prototyping

Our 3D metal printer can create products with stainless steel, tool steel, Inconel and copper. Our 3D composite printer uses continuous fibers, including carbon fiber, fiberglass, nylon and Kevlar®.

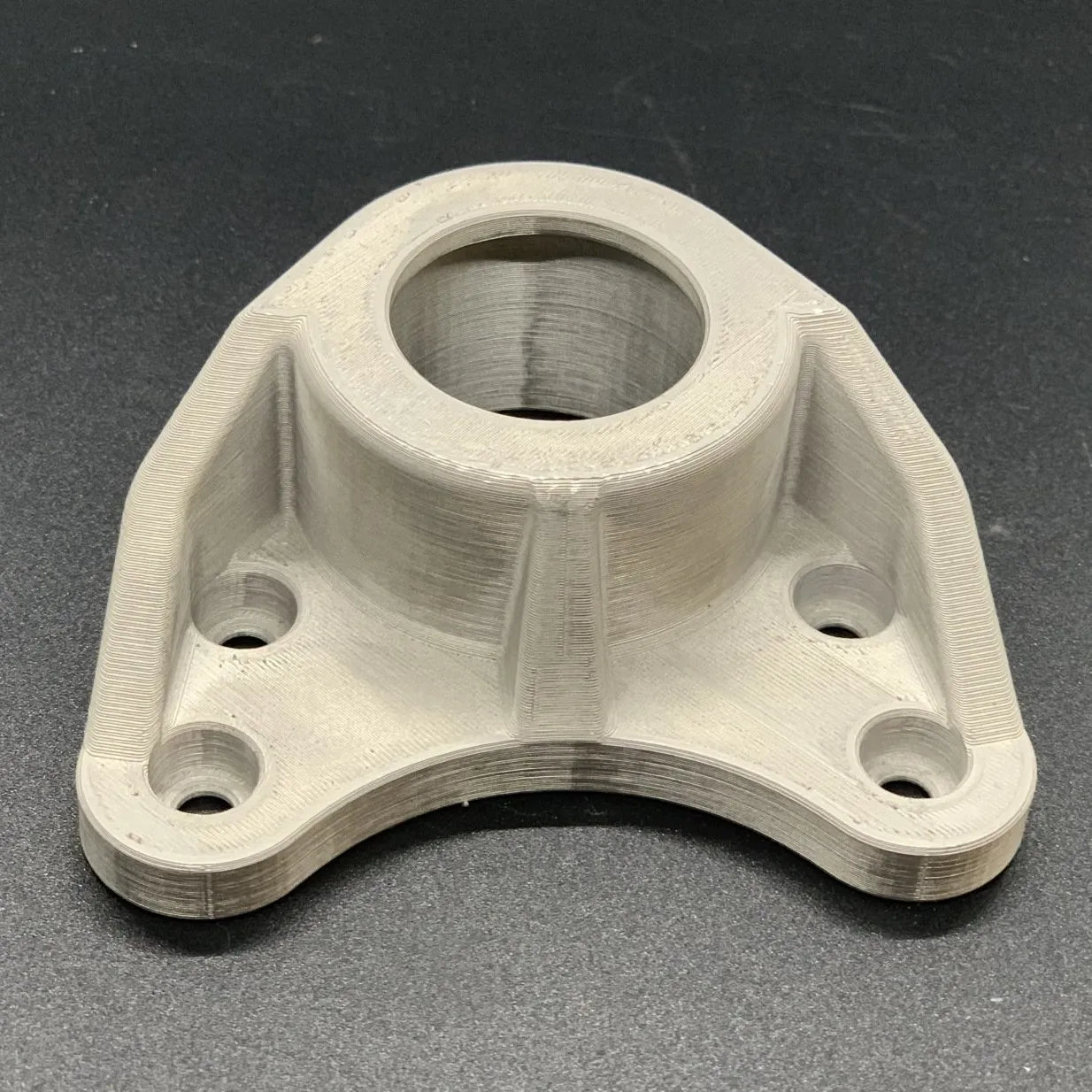

Metal 3D Printing

Typical Mechanical Properties

| Metal | 17-4 PH Stainless | Iconel 625 | H13 Tool Steel | A2 Tool Steel | D2 Tool Steel | Copper |

|---|---|---|---|---|---|---|

| UTS | 1250 MPa | 765 MPa | 1420 MPa | – | – | 193 MPa |

| 0.2% Yield | 1100 MPa | 334 MPa | 800 MPa | 1170 MPa* (c) | 1690 MPa* (c) | 26 MPa |

| Hardness | 36 HRC | 7 HRC | 40 HRC | 50 HRC | 54 HRC | – |

| Elect. Conductivity | – | – | – | – | – | 84% IACS |

| Therm. Conductivity | – | – | – | – | – | 350 W/mK |

Technical standards per ASTM E8, ASTM E9, ASTM E18, ASTM E1004, ASTM E1461. Data obtained from material datasheet, published by Markforged.

* These data represent typical values for post-sinter, heat-treated conditions.

Continuous Fiber 3D Printing

Typical Mechanical Properties

| Continuous Fiber | Carbon | Kevlar® | Fiberglass | Nylon |

|---|---|---|---|---|

| Tensile Strength | 800 MPa | 610 MPa | 590 MPa | 600 MPa |

| Heat Deflection | 105°C | 105°C | 105°C | 150°C |

| Flexural Strength | 540 MPa | 240 MPa | 200 MPa | 420 MPa |

| Compressive Strength | 320 MPa | 97 MPa | 320 MPa | 192 MPa |

| Density | 1.4g/cm^3 | 1.2g/cm^3 | 1.5g/cm^3 | 1.5g/cm^3 |

Technical standards per ASTM D648B, ASTM D790, ASTM 3039, ASTM 6641, ANSI/ESD STM11.11. Data obtained from material datasheet, published by Markforged.

Composite 3D Printing

Typical Mechanical Properties

| Composite Base | Onyx | Onyx FR | Onyx ESD | Nylon |

|---|---|---|---|---|

| Tensile Strength | 71 MPa | 71 MPa | 83 MPa | 50 MPa |

| Heat Deflection | 145°C | 145°C | 138°C | 41°C |

| Flame Resistance | – | V − 0 | – | – |

| Surface Resistance | – | – | 10^5 – 10^7 Ω | – |

| Density | 1.2g/cm^3 | 1.2g/cm^3 | 1.2g/cm^3 | 1.1g/cm^3 |

Technical standards per ASTM D648B, ASTM D790, ASTM 3039, ASTM 6641, ANSI/ESD STM11.11. Data obtained from material datasheet, published by Markforged.

Industry Leading 3D Metal Printing Equipment

Hale Manufacturing uses innovative industrial 3D printing technologies. Our Markforged 3D metal printer delivers precision and quality that matches conventional machining methods. Since 3D metal printing does not require jigs and fixtures, complex parts can be created faster while using less material. Our machine shop provides in-house post-processing to rapidly complete parts as soon as they finish printing.

How Continuous Fiber Reinforcement Works

Markforged composite printers use an innovative 3D printing technology called continuous fiber reinforcement. The 3D polymer printer extrudes a continuous filament of composite fibers according to the design, using advanced sensors to ensure precise placement of every layer.